Background information

Why you should lube your switches

by Kevin Hofer

The Qpad MK-95 is the first keyboard with switchable switches. By moving the lever, I decide whether I want to type on clicky or linear switches. I take the screwdriver in my hand and dismantle the part into its individual parts to find out how it works.

Clicky or linear: two words, two feelings that couldn't be more different. On the Qpad MK-95, I experience both in a fraction of a second by flicking a lever. Now I'm sitting in front of the keyboard, screwdriver in hand, saying goodbye to the keyboard. Because I'm taking it apart and I don't know whether it will survive. I've grown fond of it over the last few weeks, I've worked with it every day. My heart is bleeding.

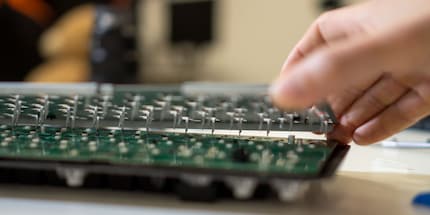

Every keyboard is basically built the same way: To see what's inside the MK-95, I have to remove the cover plate. This is attached to the housing with screws. To find all the screws, I have to remove the keycaps. Once I have loosened all the screws, I try to lift the cover plate. To do this, I use "Jimmy" - a tool for opening electrical appliances. Jimmy has helped me several times in the past. And indeed: the blade slips easily between the cover plate and the housing.

In spite of this, I can't get rid of the disc. Only after some time do I discover the solution to the puzzle: there is one last screw under the mechanism for raising the keyboard that holds the housing and cover plate together.

Now I can finally open the keyboard. As the switches are soldered to the circuit board - also known as the PCB - I can't remove them from the cover plate without unsoldering them. This is the case with most mechanical keyboards: The switches are plugged onto the cover plate, the PCB goes under the cover plate and the switches are soldered onto it from behind. I'm keeping the option of desoldering open as a last resort in case I can't figure out how the switch mechanism works any other way. I don't want to destroy the MK-95 unnecessarily. The keyboard also has a metal plate on the back of the PCB. I suspect that this has something to do with the switching mechanism.

The inside of the switch mechanism is mounted on this metal plate. What lies under the lever: a flat, round metal part with a bulge. There is a screw in this bulge. When I press the lever, the metal plate moves slightly from left to right across the PCB thanks to the mechanism.

To hold the lever in place, Qpad has placed magnets on the switching mechanism. Now I know where the satisfying feeling comes from when the lever clicks into place.

The metal plate slides unhindered over the PCB thanks to black spacers. The plate is attached to the PCB using these holders.

I loosen the screws of the spacers to see what is under the metal plate. On the other side of the plate are bevelled metal rods that protrude into the PCB and the switches respectively.

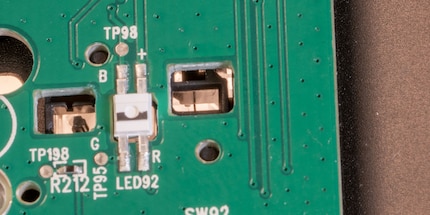

I look through the holes - through which the metal rods protrude - in the switches and see a small, fine wire. When I press a switch, the wire is pushed aside by the stem of the switch just at the moment when I hear the click and feel the trigger point. I use the screwdriver to push the wire aside and press the switch again. Now no click can be heard or felt.

The mechanism works as follows: In the "zero position", the wire is pressed to the side by the stem of the switches when tapped. This generates the clicking sound and the haptic feedback: the switches are clicky. When I move the lever - to the "on" position - the metal plate moves and with it the metal rods. These push the wire inside the switches to the side. When I press the switch now, I don't feel or hear anything when it is triggered. The stem slides unhindered from the wire into the switch. The switches are linear. Clicky and linear in one: simple, but ingenious.

In my review of the MK-95, I realised that, strictly speaking, it doesn't have mechanical switches, but optical ones. They are not triggered by a metal contact, but by an optical signal. This emits a beam of light that is blocked by the stem of the switch when the button is not pressed. If I press the switch up to the trigger point, the light beam hits a receiver instead of the stem and triggers the button to be pressed. The mechanical action, the perceptible and audible click in clicky mode, basically has nothing to do with triggering.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all