Background information

What you see is not what you get: Designs that amaze

by Pia Seidel

An eternal cycle, not excess and waste. This is the vision fuelling the concept behind textile-recycling company Renewcell, which transforms old clothes into organic cellulose fibres.

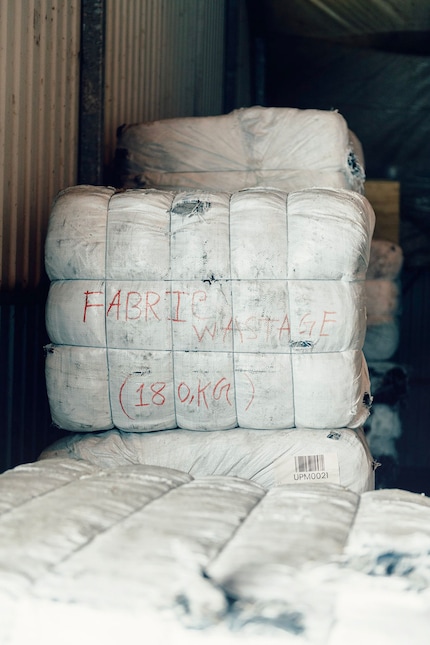

Cotton grown under unfair conditions using an enormous amount of pesticides. Litre upon litre of water consumption. Endless transportation chains resulting in dizzyingly high greenhouse gas emissions. Not to mention the tens of millions of tonnes of textile waste produced every year.

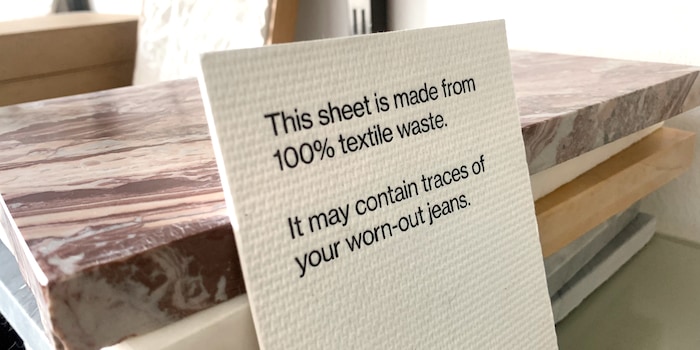

Nope, the fashion industry’s reputation ain’t great. And rightly so. Enter Swedish textile recycling company Renewcell, which has made it its mission to find sustainable solutions to some of these issues. The magic formula designed to help it achieve this? Circulose®. With its sustainable material made from 100 per cent textile waste, Renewcell was an official partner at Copenhagen Fashion Week.

The combination of the words «circular» and «cellulose» pretty much sums up the concept behind the fully recycled and recyclable material. Jeans, shirts, sweatshirts – whatever you clear out and throw away – are stripped of their buttons and zippers by Renewcell, then shredded. The same thing happens to never-been-worn factory-rejects. Colours are removed from the textile pulp, and harmful substances such as polyester are filtered out. The material left over, completing the cycle, is cellulose – an organic, biodegradable compound found in trees, green plants and cotton.

The pure cellulose is then dried and pressed into sheets, which continue their cyclical journey as stacks of material. These go on to factories, including those belonging to Calvin Klein, Tommy Hilfiger and Ganni, which process Circulose® into yarn and use it as either a base material or for the production of viscose, lyocell and modal.

«By 2030, we aim to have recycled the equivalent of over 1.4 billion T-shirts,» the Swedish company promises on its website. The goal is to make the production of new raw materials using cotton, oil or wood, as well as residual waste a thing of the past as soon as possible. «Circulose® is the crucial missing link for a circular economy for textiles.»

Always in the mood for good hits, great trips and clinking drinks.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all