Background information

Quagga mussel problem: How to clean your SUP when changing waters

by Siri Schubert

Diving into the ocean, feeling the power of the water, being carried along by the waves – all of this makes surfers feel closely connected to nature. The materials and manufacturing methods many surfboards are made with, however, are anything but environmentally friendly. Companies such as IPSO award-winner Agit Global have their hearts set on changing this.

Surfing often goes hand in hand with a commitment to marine conservation. After all, nobody wants to get a mouthful of plastic or sewage when they wipe out. As a result, many surfers volunteer for organisations like the Surfrider Foundation or Surfers against Sewage, regularly taking part in beach clean-ups.

But here’s the rub. Most surfboards – the very things that make this action-packed water sport possible in the first place – aren’t very environmentally friendly. And yes, jetting off to exotic surfing destinations and wearing mineral-oil-based wetsuits don’t help matters either. Not to mention the 2024 Olympic Surfing competitions/ scheduled to take place in Tahiti. But that’s another story.

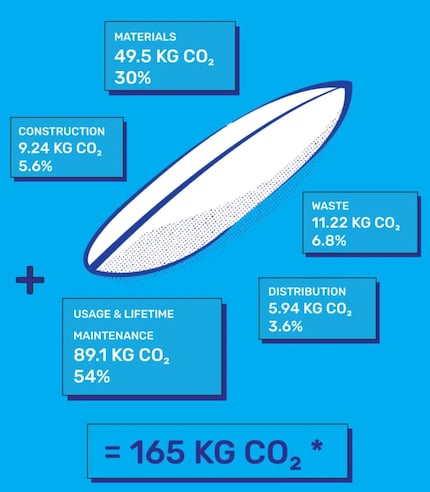

If you’re not a numbers nerd, feel free to skip this section. Otherwise, read on. According to calculations done by the organisation Wavechanger, around half a million new surfboards are sold worldwide every year. Over its entire life cycle, a typical 6-foot shortboard emits an average of 165 kilogrammes of CO₂, with the figure reaching 217 kilogrammes for longboards. Wavechanger says the amount of CO₂ emitted by a shortboard equates to the amount produced by a petrol-powered car over a distance of roughly 700 kilometres.

That’s a lot. Too much, say both surfers and some surfboard manufacturers. In fact, the latter are making a conscious effort to find environmentally friendly materials and production methods. Some boards are now available with mushroom or algae-based foam cores. In order to serve the growing market for surfboards, companies are also working on production methods that reduce CO₂ emissions, waste and the use of adhesives and resins harmful to the environment.

One of these manufacturers is Taiwanese firm Agit Global. According to the manufacturer, its Innovative Smart Lamination process is designed to reduce carbon emissions during manufacturing. Instead of using epoxy resin and adhesives, the board is constructed using steam and heat. This is meant to make it more resistant (for any surfers out there, less prone to delamination) and stop it absorbing as much water if it’s damaged. Plus, using precise, computerised numerical control (CNC) machines for milling allows the manufacturer to create custom designs, producing less waste. The company says it sources all raw materials locally, no more than two hours’ drive from the factory.

There’s another upside to the board: the production method used to manufacture it is designed to make it completely recyclable. The raw materials can be reused to make surfboards. This is an important innovation, as traditional surfboards made with epoxy resin and adhesives are notoriously difficult to recycle.

The jury of the international sports expo ISPO also recognised this in their statement: «The new surfboard-construction developed by AGIT Global blends performance with environmental responsibility. The renunciation of toxic materials is a big step towards sustainable surfboard production.» Agit Global plans to test the process for manufacturing other types of water sports equipment in the future.

Header image: Shutterstock/Photographer Artem FirsovResearch diver, outdoor guide and SUP instructor – I love being in, on and around water. Lakes, rivers and the ocean are my playgrounds. For a change of perspective, I look at the world from above while trail running or flying drones.